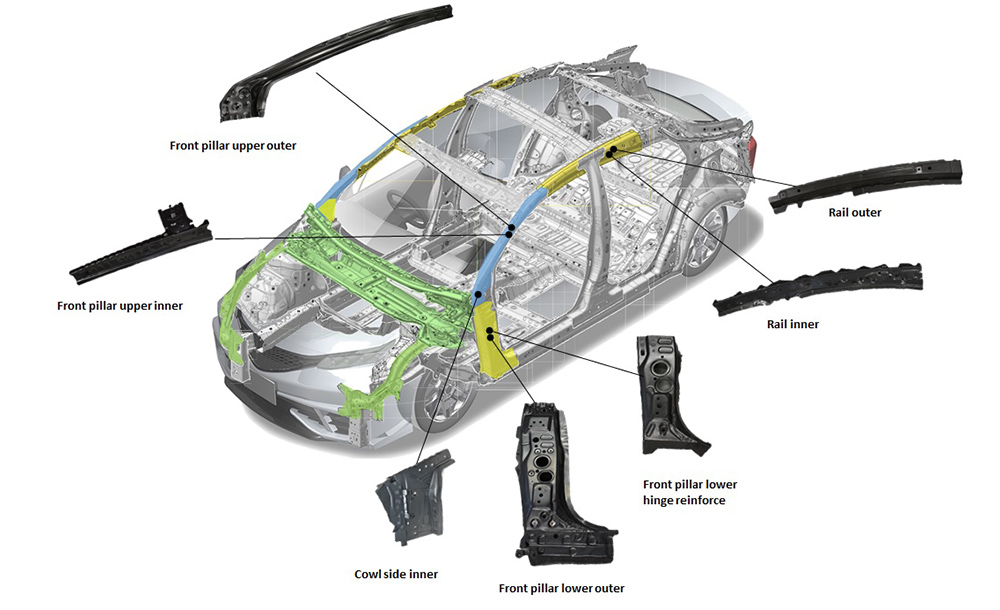

Body parts using 1470MPa ultrahigh tensile strength steel

Initiatives for ultrahigh tensile strength steel

Front pillar upper outer using 1470MPa ultrahigh tensile strength steel has been adopted for the first time in Toyota vehicles which is used in new prius released on January 10th, 2023.

1470MPa ultrahigh tensile material has much higher strength than general steel plate and can ensure sufficient strength even if plate thickness is reduced

for lighter weight.

However, it is difficult to form because the material does not stretch easily, and it is difficult to ensure dimensional accuracy because of its large spring-back(the force which the material tries to return to its original state)after forming.

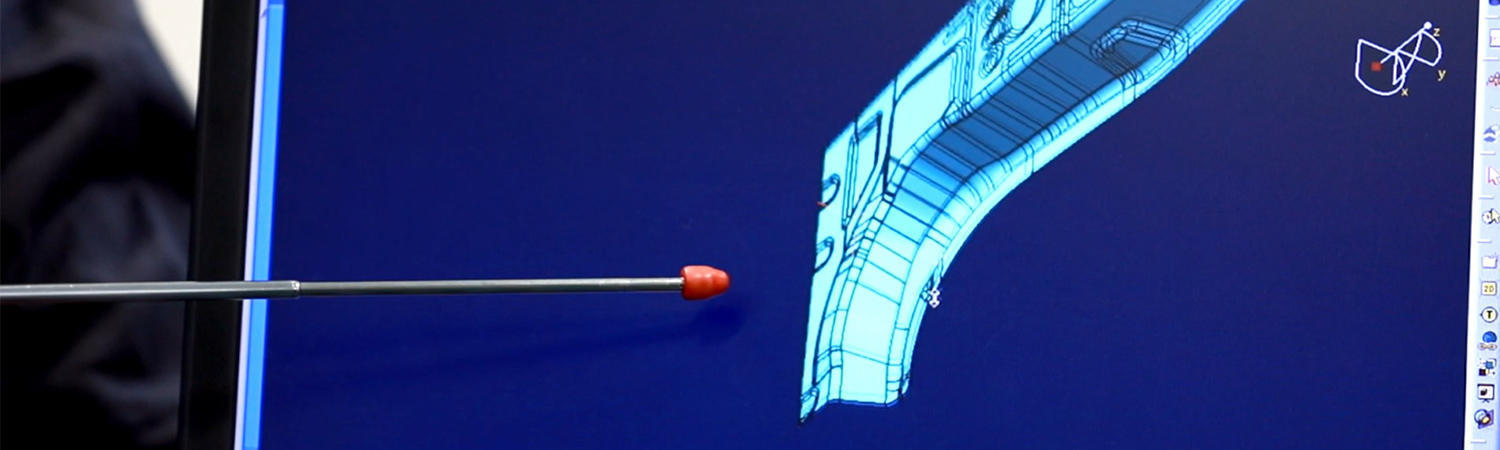

In order to overcome these issues, we incorporated the know-how accumulated in mass production of ultra high tensile parts and considered the optimum shape

through forming analysis.

Initiatives for making proposals to the customer

In the past, Futaba proposed shapes to customers for individual products, but this time, we used CAE analysis to propose a structure from early stage for medium-scaled assembly(the front pillar zone)with both performance and manufacturing in mind, and it was adopted.

Contribution to society

For the front pillar upper outer of the previous generation model, hot stamped material was used, but changing to a 1470MPa ultrahigh tensile material is contributing to reductions in CO2 emissions and costs.

In addition, for the front pillar lower, cowl side inner, and rail outer and inner, 1180MPa ultrahigh tensile material stronger than the previous model was adopted in consideration of weight reduction and collision safety.

◇Car body image

Blue: 1470MPa ultrahigh tensile body parts, Yellow: 1180Mpa ultrahigh tensile body parts, Green: other main body parts adopted this time