Processing of ultrahigh tensile strength steel

In press forming, increasing the strength of and decreasing the weight of body parts are essential technologies in order to comply with safety regulations and fuel consumption standards that will grow increasingly stricter in the future.

In response, we are engaged in cold press forming of ultrahigh tensile strength steel that is high in both strength and productivity.

Processing of ultrahigh tensile strength steel is to form a material of ultrahigh tensile strength steel, the tensile strength of which is 1.5GPa-class, by cold press.

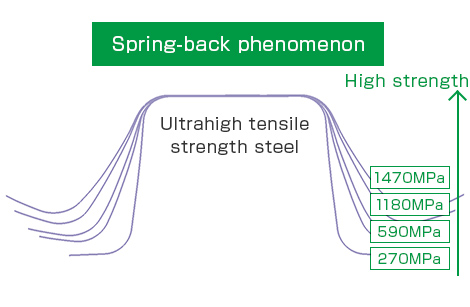

In processing ultrahigh tensile strength steel, it is difficult to secure dimensional accuracy because of the significant spring-back phenomenon specific to the

material of ultrahigh tensile strength steel that occurs when the material is bent.

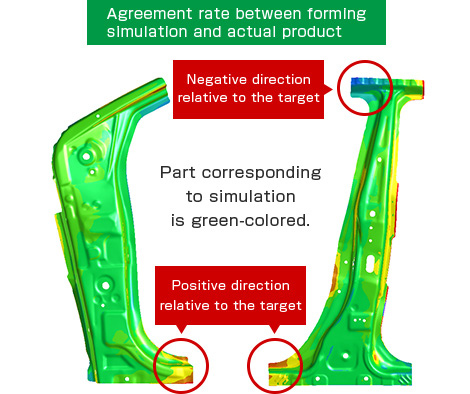

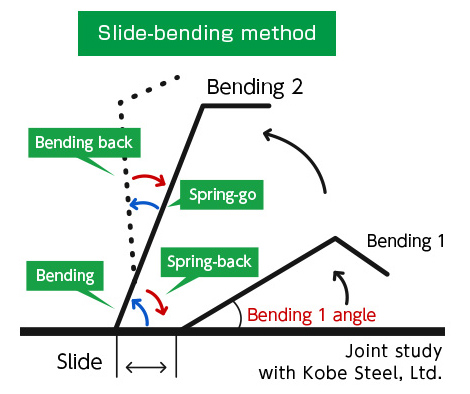

To counteract this, accuracy is improved by developing slide-bending and other methods through the utilization of forming simulation.

For ultrahigh tensile strength steel with such difficulty in processing, we will continue to establish technology for complex shapes and global deployment in the future.

Hot stamping

- Hot stamping is a technology to increase the strength of sheet steel as it is heated to a high temperature and press-formed, and then rapidly quenched by holding it in dies. Lighter and stronger products can be made because processing can be performed while increasing strength high.

Since once-heated sheet steel is press-formed, complex shapes can also be handled.