Production process innovation

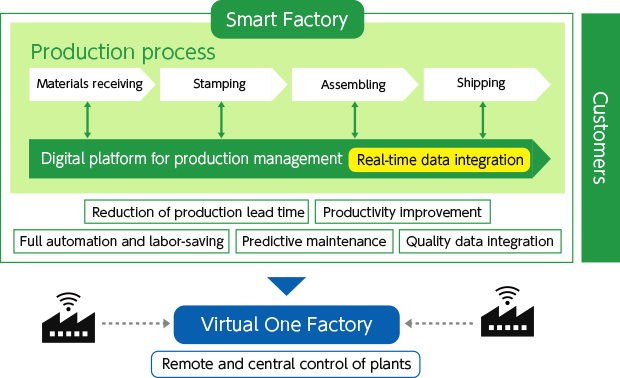

We remain committed to innovating the production process with digital support. By further enhancing monozukuri capabilities(Smart Factory)and pursuing Virtual One Factory, we aim to increase productivity by 15% and halve the indirect processes at plants.

Further enhance monozukuri capabilities with digital support(Smart Factory)

The system integrates real-time operational data in the production process into a digital platform for production management. We utilize the data for improvements and labor-saving to stream-line production sites.

We will develop a model line by FY2023. The model line will be deployed in Japan with the aim of global expansion in FY 2025.

Build a Virtual One Factory

Linking data of production sites enables remote and central control of production management and indirect businesses. We aim to centrally control the management operations from a single domestic site in FY 2025, thereby reducing the number of processes of indirect businesses.

Initiatives

Smart Factory

-

Reduction of production lead time

The method of conveying information on production instruction is switched from returnable kanban to data transfer.

By eliminating physical delivery of kanban and sorting tasks, we aim to prevent information from being retained in the process from production to shipment, and reduce the production lead time. -

Full automation and labor-saving

We will adopt and accelerate the introduction of trackless AGVs that eliminate the need for installing guiding rails. Under the system, we will promote full automation of parts delivery tasks by linking the receipt of finished goods and the supply of parts in accordance with production progress.

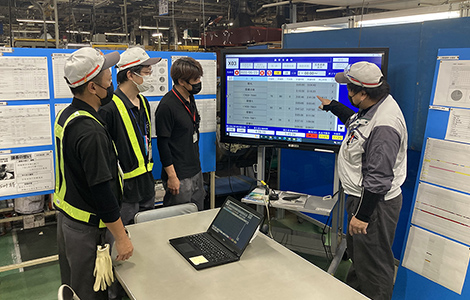

Acceleration of productivity improvement

-

Production performance and causes for suspension will be automatically acquired from the signal of production facilities. This helps us to capture the production status in real-time and promptly address anomalies and make improvements, thereby enhancing productivity.

In addition, such timely production information will be linked to various information to develop a digital platform for production management. -

Virtual One Factory

Concentration of production management operations

- We will conduct real-time monitoring of on-site conditions from a remote area, concentrate plants' administrative operations, and control all plants as one. Under the system, we will reduce management person-hours.

-

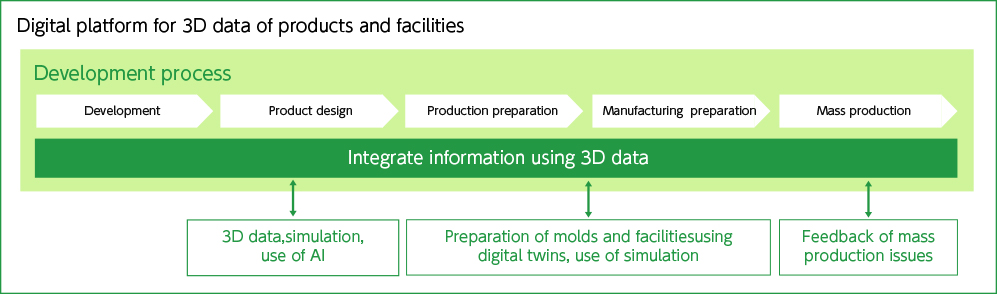

Transformation of development process

Futaba is working to transform its development process from the traditional pass-the-baton type development by each process to a more agile, parallel development in the digital space using 3D data of products, facilities and plants, thereby aiming to halve the development lead time.

Overview of the development process transformation

Developing a digital platform for 3D data of products and facilities, we integrate information using 3D data throughout the process from development to mass production.

Furthermore, we facilitate simulation development using 3D data. With the help of feedback from actual product data, we work on shortening the development period and reducing rework.

Initiatives

Introducing AI to product design

Traditionally, drawings or other documents are used to instruct production preparation following the product design process;nowadays they have been gradually replaced by 3D data. Futaba is working on reviewing the product design process leveraging 3D data. We introduced AI trained with the optimal process, design know-how and accumulated knowledge, etc., and use it as a design guide that provides designers with points worthy of note. By reducing uneven quality of designs, AI helps prevent redesigning and accelerate the decision-making process on the shape of products.

Utilizing simulation for production preparation

- We utilize simulation to examine logistics within a plant by replicating a layout of the entire plant in the digital space. We visualize and optimize delivery routes and examine the space in advance within the digital area to reduce the on-site manufacturing preparation processes after facility installation and save labor in the logistics within the premises after the start of mass production.

-