Basic approach

We believe that the safety and health of each one of our employees is a precious asset and management resource. Based on the concept that "Safety always takes first priority," we seek to ensure workplace environments facilitating safety and ease of work, respecting the personalities and individuality of our employees, while striving to ensure their satisfaction and fulfillment.

- Basic policy on safety and health

-

- 1.Safety and health are prerequisites for business activities, and each and every employee must act while placing the highest priority on safety.

- 2.Futaba complies thoroughly with related laws, basic rules and other requirements, and raises awareness of safety and health through education.

- 3.Futaba works on safety and health activities by establishing a management system and clarifying responsibilities and roles.

- 4.Futaba clarifies workplace risks, implements measures in accordance with the nature of risks, and recognizes that health that minimizes potential risks is the basis of everything, and all employees continue to use ingenuity and make efforts to create healthy bodies and comfortable workplaces.

- 5.Futaba works in cooperation with local communities on environmental improvement activities that can gain the sympathy of society for the creation of a better future for local communities.

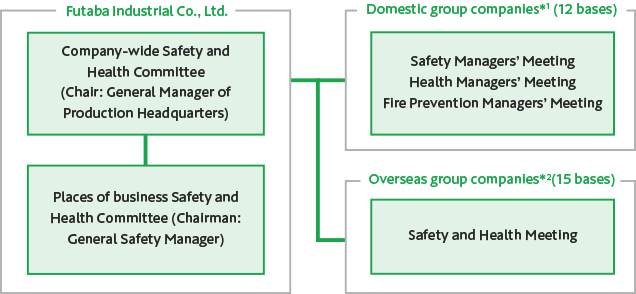

Promotion System

At Futaba, under the auspices of the Company-wide Safety and Health Committee(Chair: General Manager of Production Headquarters), committees have been established in each place of business, workplace and group company, and they are working on the continuous improvement of safety and health.

In addition, Futaba supports the establishment of systems that enable each place of business to establish safety and health management independently at a top-level for each of their countries, taking into account the laws, regulations and various systems of each country.

- *1. Domestic group companies : 5 production sites of domestic subsidiaries

- *2. Overseas group companies : 15 production bases of overseas subsidiaries

Creating a workplace culture where employees can work safely and with a sense of reassurance

We have established the PDCA cycle of occupational health and safety activities in each of our workplaces and put in place a structure for greater promotion of and enhanced education on our occupational health and safety management system (OSHMS)*3, thereby improving our workplace safety culture.

In addition, in our work to create an environment where everyone can work safely and with peace of mind, we are striving to create workplaces with risk mitigation measures to prevent disasters from happening. This is achieved by using educational video tools in multiple languages, improving individual risk sensitivity

through measures such as creating time for safety education, workplace observation activities by position, and risk assessment*4 promotion activities. We will also focus on developing human resources who strictly observe work rules.

- *3. Occupational health and safety management system is a system in which a business operator voluntarily manages occupational health and safety on an ongoing basis to improve occupational health and safety levels on its worksites.

- *4. Risk assessment is a method that comprises the following processes: identifying potential worksite risks or hazards; assessing risks by combining the severity of industrial accidents and health problems caused by the identified risks or hazards(i.e., the level of harm to persons)and the probability of the accidents; prioritizing risk control measures based on the magnitude of the assessed risks; and examining how to eliminate or reduce the risks.

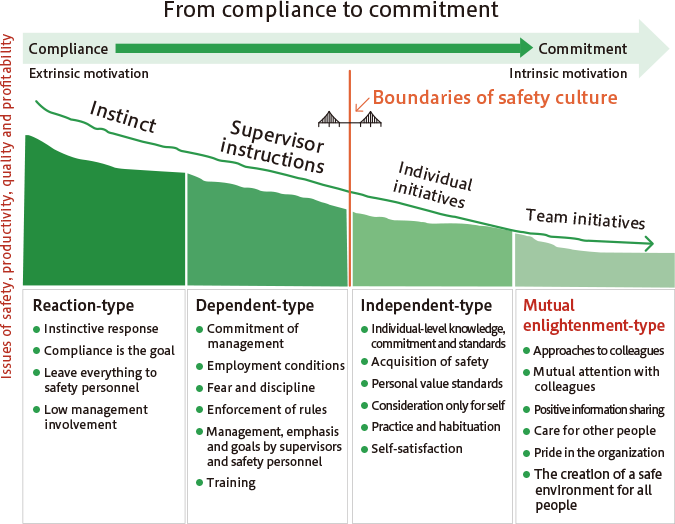

Building of a culture of mutual enlightenment and safety in the workplace

At Futaba, we are working on the building of a "mutual enlightenment-type" safety culture that encourages employees to share information positively and pay attention to each other.

Source: DUPONT Bradley Curve

Industrial accident prevention initiatives

We implemented STOP 6*2 initiatives and focus on risk reduction activities in particular to prevent accidents arising from transportation of heavy objects and accidents related to vehicles (forklift work), both of which have a high probability on our worksites. We are working to identify potential dangers in operations, make improvements, and reduce risks.

- *2 STOP 6 Activities to prevent accidents from happening by focusing on six types of accidents analyzed from examples of past accidents as critical accidents. The six are: being caught in a machine, collision with a heavy object, collision with a vehicle, falls, electric shocks, and contact with a heated object.

The 4 accidents that require time off from work occurred in Japan during 2022 while 0 accident occurred related to death and physical harm. When seeing detail of these accidents, accident caused by "equipment" factors has not occurred, but accidents attributable to "human" factors have occurred such as from work process and environment, lack of care and confirmation.

Therefore, to create safe environment where is able to follow work rule, we are enhancing work environment by 4S & 5Tei activities*6.

Also, to create safe environment where is able to develop people, we have examined cause of unsafe condition and unsafe action more in detail at disaster/minor incident management meeting and have taken certain measures to the causes. In addition, as part of the activity to prevent industrial accidents, we provide hands-on training related to such as crane work, and skills enhancement training for preventing disaster.

- *5. STOP 6: Activity to prevent accidents from happening by focusing on six types of accidents analyzed from examples of past accidents as critical accidents and promote prevention activities. The six are: being caught in a machine, collision with a heavy object, collusion with a vehicle, falls, electric shocks, and contact with a heated object.

- *6 4S & 5Tei Activity---Activities to promote safe and reassured workplace by visualizing normal and abnormal condition (Seiri & Seiton & Seiso & Seiketsu=4S) and creating environment to be able to follow workrule (Teiro & Teiryo & Teichi & Teimei & Teishoku=5Tei).

Results in FY2023

| Non-consolidated and domestic group companies*1 | Overseas group companies*2 | |

|---|---|---|

| Number of accidents that require time off from work | 4 | 20 |

| Frequency rate of work stoppages | 0.33 | ー |

Safety education

Under our belief that it is possible to achieve a zero accident record, Futaba prepares standard work procedure documents and are working to ensure that basic practices are thoroughly carried out, so that they follow proper work procedures to achieve zero-accident workplaces.

In addition, we are carrying out activities to prevent past disasters from fading away, as well as holding annual hands-on training for workers, in order to ensure all employees are keenly aware of the importance of following rules.

Fire prevention initiatives

As part of the activity to prevent fires, we focus on preventing fires caused by sparks and spatters as well as electrical systems and devices. We take thorough countermeasures across Futaba for the identical and same type of equipment with which fires occurred inside and outside of our workplaces in the past. We also raise awareness of never letting a fire happen by identifying potential fire risks in each of our workplaces, mapping the risks, and always visualizing and managing them.