Basic approach

We are working to promote resource-saving, and recycling, considering the lifecycle of resources.

We aim to reduce environmental impact by decreasing the amount of steel usage through activities that improve material yield and reduce waste within the production process. Additionally, we are implementing activities to reduce the amount of oil used and the amount of waste produced, with the goal of promoting coexistence between people and nature.

Currently, we has begun to move towards promoting a circular economy. We are considering the recycling of resource and material losses (such as waste) in our manufacturing processes. We view this initiative as an important step in protecting the natural environment.

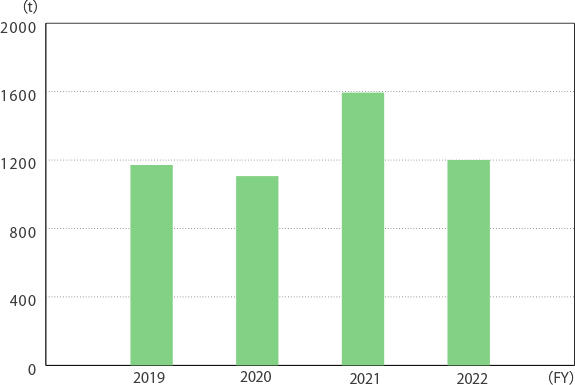

Initiatives to waste reduction

We are aiming to reduce the amount of waste produced (including general waste) by 11% compared to 2019 levels by FY2030.

We are working to limit waste generation through improved operational efficiency. Additionally, we believe that waste can become a resource if properly sorted, so we are striving to reduce the amount of waste by enhancing our sorting accuracy.

In response to the problem of groundwater flowing into stamping pits at some of our plants in FY2021, although water sealing measures have been implemented and are showing some improvements, abnormal values still persist. Therefore, starting in the FY2024, we have condusted trials aimed at purifying this wastewater and utilizing water resources effectively.

Waste output(Domestic group companies)

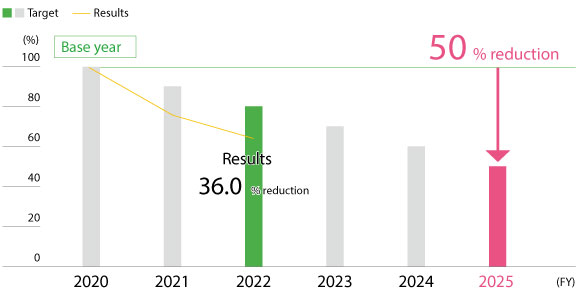

Initiatives to reduce steel usage

Improving material yield is an important activity in pursuing minimization of material needed to make one product. Each production site makes steady and repeated efforts to reduce the size of materials by millimeters. Countermeasures against root causes are also important in preventing the outflow of defective products. Therefore, we also focus globally on activities to minimize loss and waste and reduce waste within the production process (reduction of 50% or more compared to FY2020 by FY2025).

By using non-destructive testing equipment, we reduce scraps from daily inspections and promote overall resource-saving.

Reduction of waste within the production process(Non-consolidated)

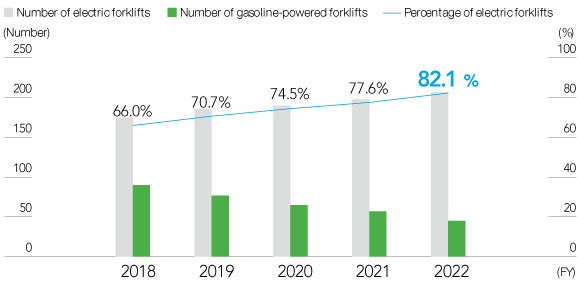

Initiatives to reduce oil usage

To reduce the amount of fuel used for gasoline-powered forklifts, which account for nearly 70% of all oil use, we are shifting to electric forklifts and small electric vehicles. In FY2023, 86.8% of forklifts were shifted to electric ones. Going forward, we will continue to reduce the overall number of forklifts by improving distribution.

Also, to contribute to making effective use of resources through recycling, the processing oil for product processing is filtered and reused as much as possible.

Shift to electric forklifts (including domestic Group companies)

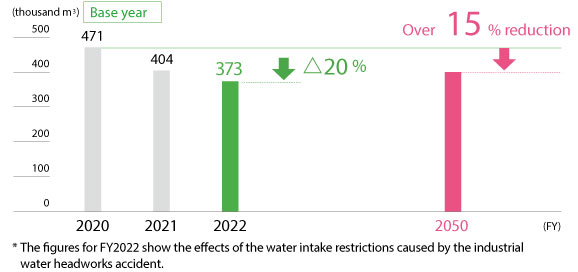

Initiatives for water resources

As climate change progresses, the importance of water resources is increasing year by year. In Japan, we are continuing efforts to achieve our target of reducing water intake volumes by 15% from the FY2020 level by FY2050. In FY2021, production volume decreased, and in FY2022, water usage decreased due to an accident at the water intake source, but in FY2023, production recovered to the level of the previous year, and the trend is toward further reductions.

In order to maintain a sound water cycle, the water quality of discharged water is controlled at a level that is 10% stricter than the wastewater standards of each region. Group companies in Japan and overseas have also set similar targets, and are working to secure water resources on a global basis.

Water intake volumes (non-consolidated)