Response to Carbon Neutrality(CN)

As measures to combat social issues such as extreme weather events sparked by global warming, we are striving to reduce CO2 emissions through comprehensive daily improvements in Scope 1 and 2 emissions, and we are steadily achieving results globally.

Following the release of the Sixth Report of the IPCC, we have tightened our CO2 emissions reduction targets for plants under the 1.5°C standard.

Furthermore, with regard to Scope 3 (upstream) emissions, we are focused on (1) raw materials--which account for the majority of Scope 3 CO2 emissions--and are actively working to mitigate CO2 emissions through product development that results in reduced usage while also improving the yield.

- CO2 emissions

reduction targets for plants

(Revised in October 2024*1) -

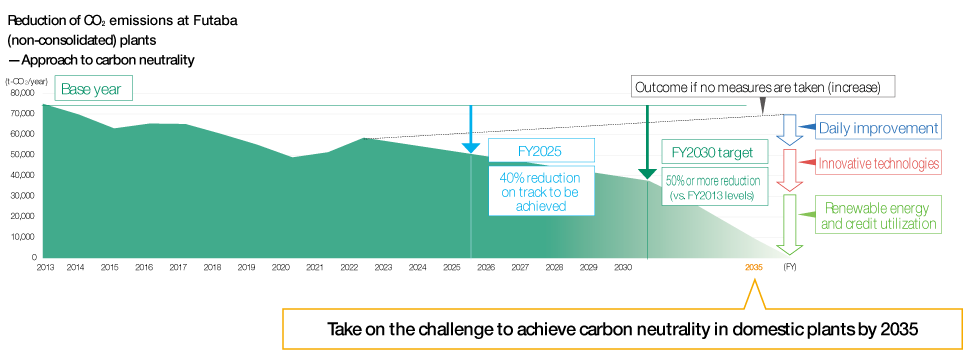

Non-consolidated and domestic and overseas Group companies: Reduction of 50% or more by FY2030 compared to FY2019 (Annual 4.6% reduction)

2035: Take on the challenge to achieve carbon neutrality in domestic plants*1 The reduction targets before the revision are as follows.

Non-consolidated: Reduction of 50% or more by FY2030 compared to FY2013 (Annual 3% reduction)

Domestic and overseas Group companies: Reduction of 33% or more by FY2030 compared to FY2019 (Annual 3% reduction)

2035: Take on the challenge to achieve carbon neutrality in domestic plants

Life Cycle CO2 Reduction

In addition to CO2 emissions reduction activities at our plants, we are implementing additional initiatives from a life cycle perspective.

- Upstream

-

Scope3

-

(1)Raw materials

-

(4)Transportation

/Delivery -

(7)Commuting

*Other:(2)Capital goods,(3)Fuel and energy-related activities not included in Scope 1 and 2,(5)Waste,(6)Business travel, and(8)Leased assets

-

Reduction of CO2 emissions in materials and parts

- Reduction of materials purchased through weight reduction utilizing technologies such as cold-stamped UHTSS for body parts

- Shift to eco-certified products(mufflers, exhaust manifolds, DPFs, and canisters)

- Collaboration and target setting with suppliers by rolling out our initiatives

Reduction of CO2 emissions related to distribution

- Enhancement of compatibility between suppliers and reinforcement of backup systems to optimize distribution considering regional characteristics

- Reduction in the number of die trials using CAE analysis to reduce the number of transpotrs

- Futaba

-

-

Scope1

Fuel combustion

-

Scope2

Use of electricity

-

Efforts to achieve zero CO2 emissions from plants

Daily

improvement

- Reduction of power consumption of robots while idle

- Proper consolidation of low-use lines to keep good production efficiency(yosedome)

Innovations in production engineering

- Producing multiple parts per stamping cycle

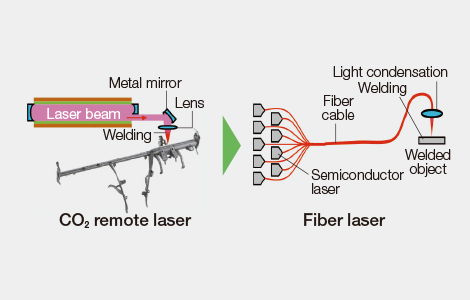

- Change of laser welder types(CO2 → fiber)

- Reduction of compressor air supply pressure

Utility

update

- Replacement of lighting to LED in plants

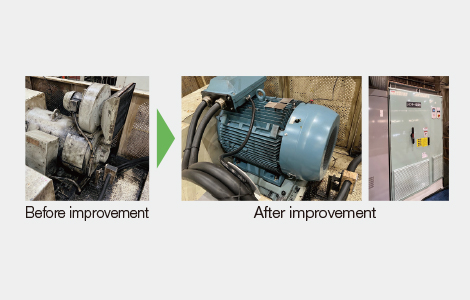

- Shift to inverters for cooling water pump motors

- Installation of thermal insulation material in the paint-drying furnace

Renewable

energy

- Installation of solar panels

- Downstream

-

Scope3

-

(11)Use of products

-

(12)Disposal of products

*Other:(9)Transportation/Delivery, (10)Processing of products, (13)Leased assets,(14)Franchises,(15)Investments

-

Reduction of CO2 emissions at using stage

- Weight reduction through replacement with cold-stamped UHTSS for body parts

- Shift to eco-certified products with small size and high performance, to reduce environmentally hazardous substances, noise, and weight

Efforts to reduce waste

- Reduction of waste through promotion of general-purpose use and reuse of equipment

- Incorporation of CO2 emissions into management decisions on replacement or new construction of equipment*2

*2 We are working on replacing CO2 emissions during production with prices in the operation approval form when any equipment is to be replaced, newly constructed, or substantially renovated. We are further considering using internal carbon pricing (ICP*3) as an indicator for investment decisions.

*3 Internal carbon pricing (ICP): One type of carbon pricing

Reduction of CO2 emissions at Futaba(non-consolidated) plants

-Approach to carbon neutrality

Promotion System

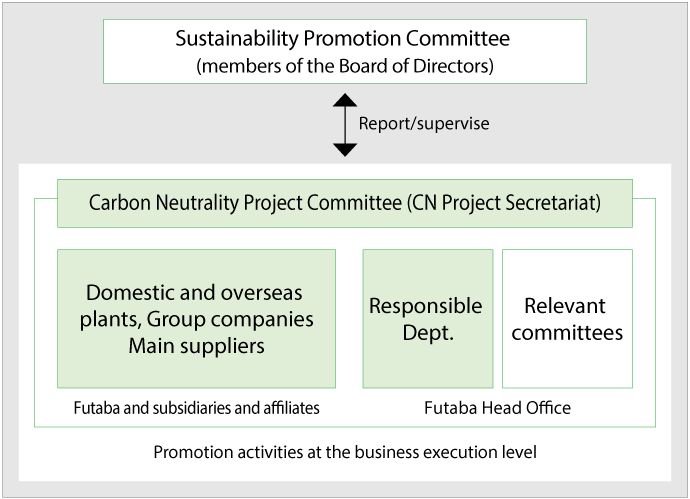

Futaba reports and supervises its management approach to climate change and the risks and opportunities associated with its business at our Sustainability Promotion Committee.

As one of the Company's priority issues (materiality), environmental issues including climate change are incorporated into the medium-term management plan and corporate global policy after approval by the Board of Directors, and the Company is working to achieve its goals.

The Carbon Neutrality Project Committee deliberates and establishes the Futaba Group's policies and targets, and each responsible department formulates action plans, deploys them to the Futaba Group, and manages their progress globally. In addition, we have expanded this to our suppliers in Japan, and are promoting measures throughout the supply chain. Progress is reported to the Sustainability Promotion Committee, while improvement activities and the reexamination of targets based on changes in the business environment and business performance are discussed by the CN Project Secretariat and each responsible department, and are reflected in the policies and targets.

Promotion system chart

"Monozukuri" considering the impact on global warming and climate change

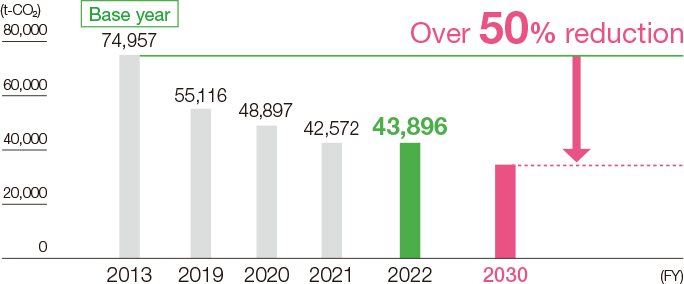

CO2 emissions(non-consolidated)in FY2023 ended up with reduced by 14% compared to FY2019 due to aggressive improvement activities.

Amount of CO2 emissions(non-consolidated)

Case 1 Replacing with fiber laser welders

- We have been replacing CO2 remote laser welders in the mass production facility of instrument panel reinforcements with lower-power-consumption fiber laser welders.

We expect to cut approximately 600 tons of CO2 emissions going forward.

Case 2 Efforts to minimize electricity and air usage

- We are promoting an 'Action Plan' aimed at minimizing electricity and air usage across all plants, implementing numerous initiatives to reduce CO2 emissions. In the fiscal year 2023, these efforts have resulted in a reduction of approximately 840 tons of CO2 annually.

Case 3 Using renewable energy

- In October 2024, we added solar power generation at Kota plant. This system will cover approximately 9% of the monthly electricity consumption of Kota plant. We also plan to implement this in other plants in the future. Additionally, the introduction of solar power is being promoted in our domestic and overseas group companies.

-

Solar panels at Kota plant